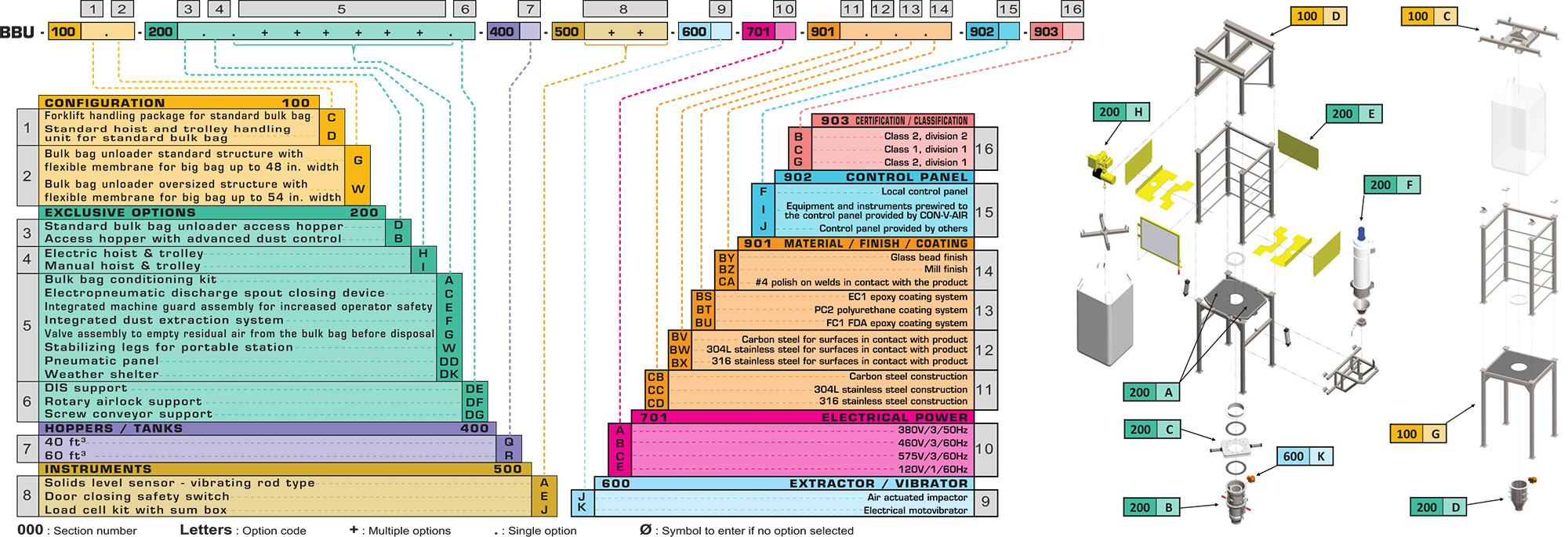

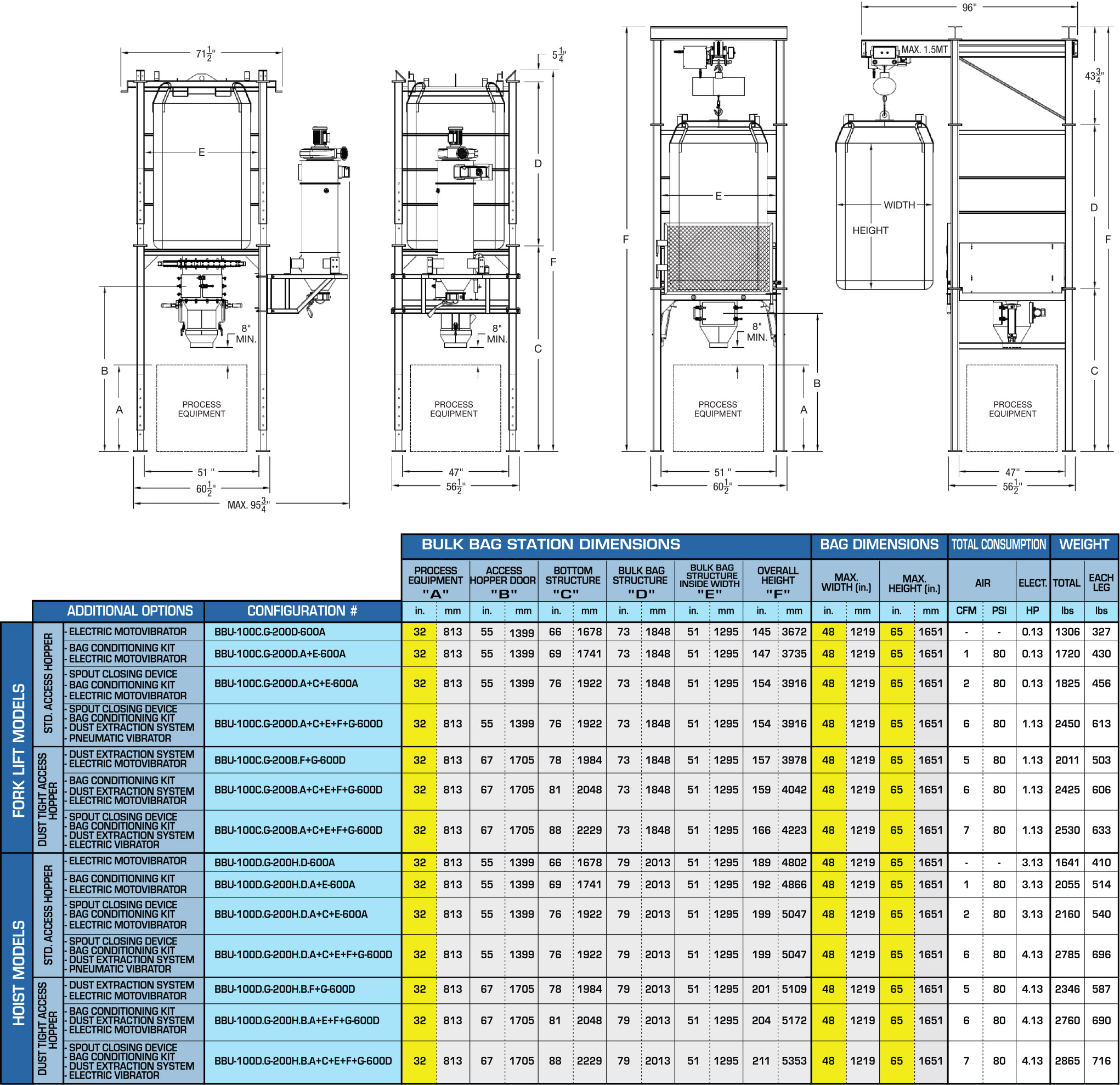

BBU - Bulk Bag Unloader

With more than 40 years of experience in bulk bags unloading, CON-V-AIR has an incomparable level of engineering, designing and fabrication for standard or made-to-order applications. Its robust construction makes our stations durable and sturdy during transport, installation and operation. CON-V-AIR's unloading systems are optimized for maximum security and offers a wide range of options for numerous application and bag sizes. Its integrated dust collection system and one of kind conditioning kits will meet the requirements for any kind of product.

Applications

- Food processing

- Power Plant

- Plastic Industry

- Mining

- Wastewater / Water Treatment

- Etc.

Capabilities

- CWB W47.1 (W59) and ISO 9001:2015

- In-house quality control

- Durable coating according to any applications

- OEM system installation

- Factory prewiring, preassembled and tested

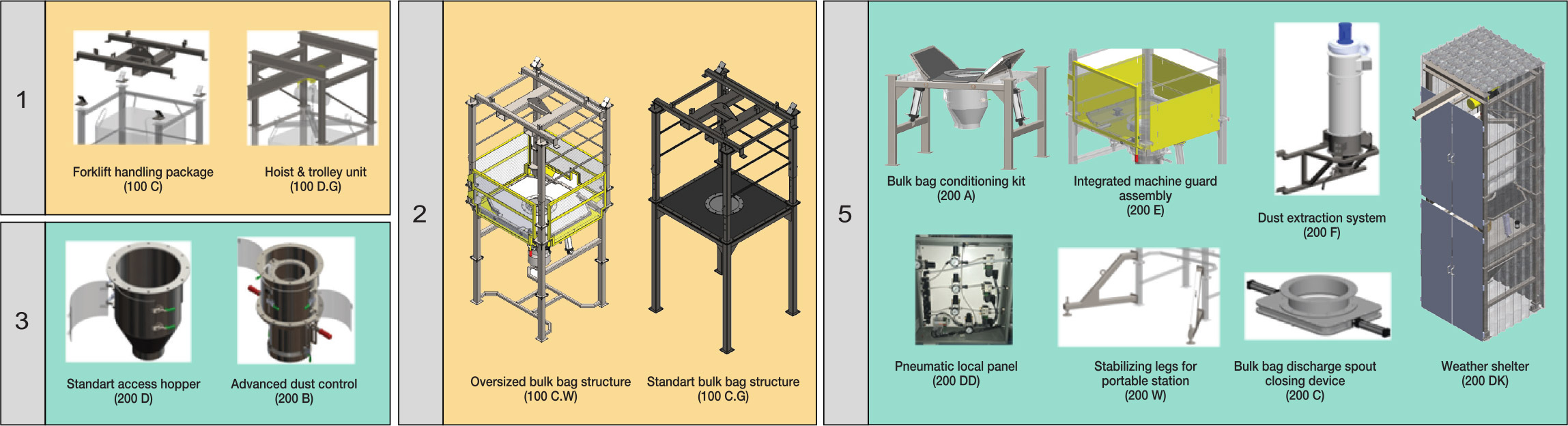

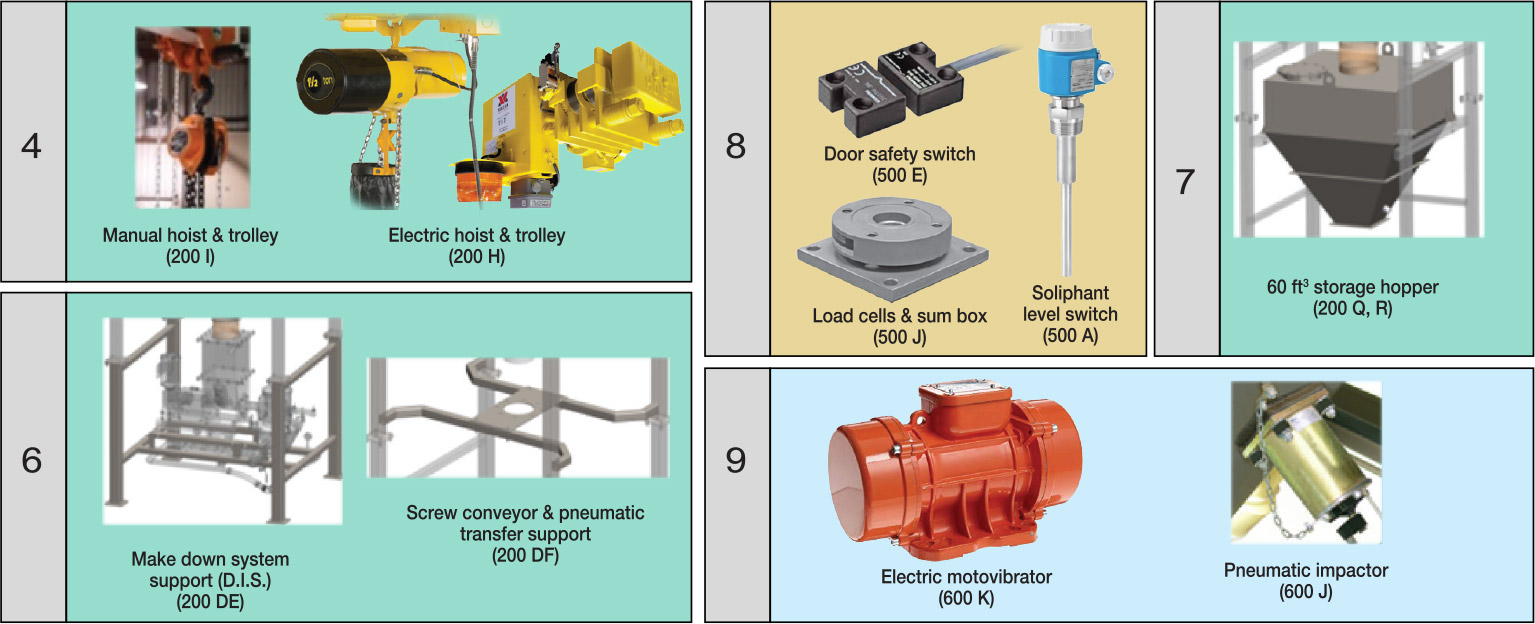

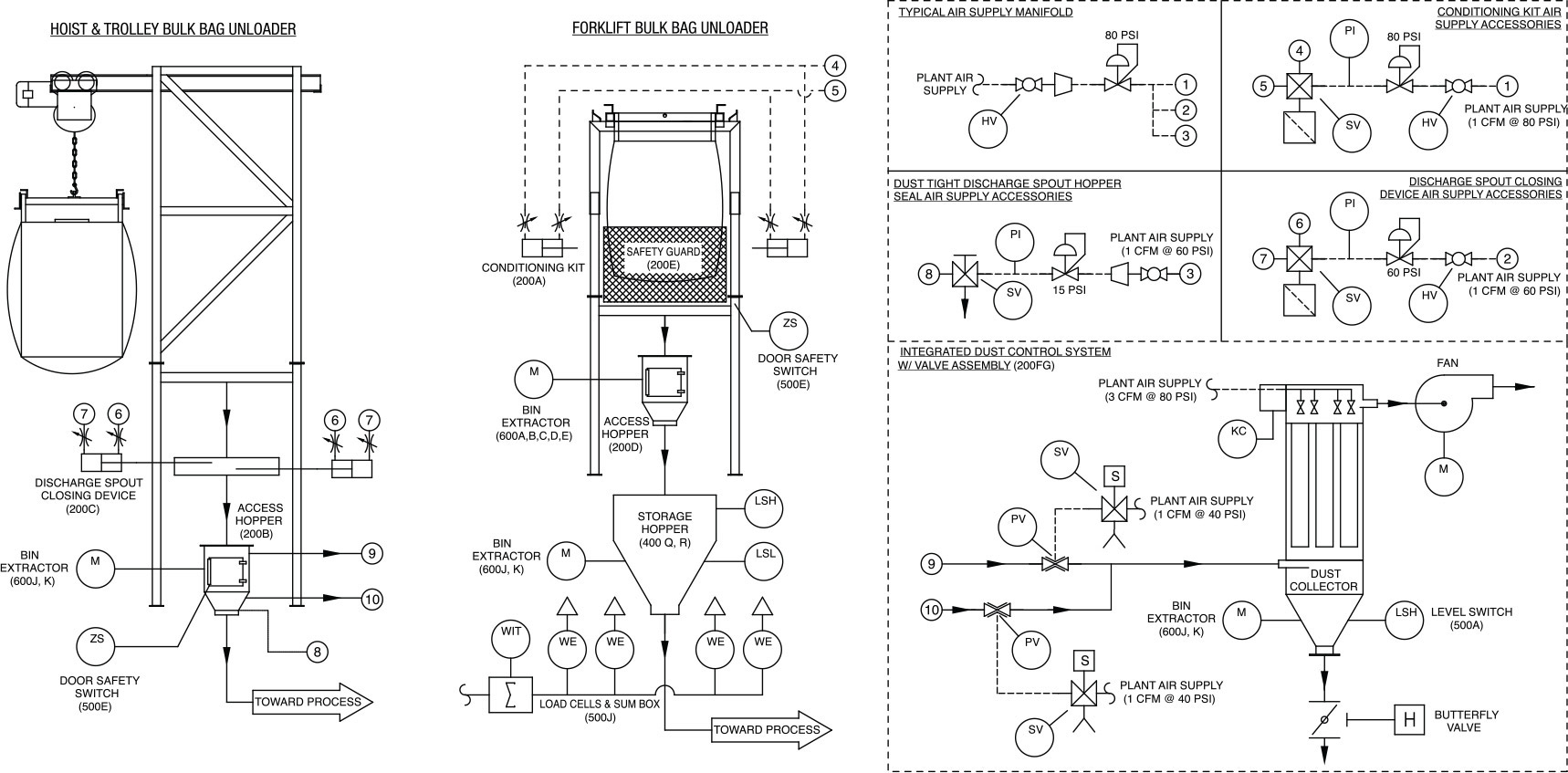

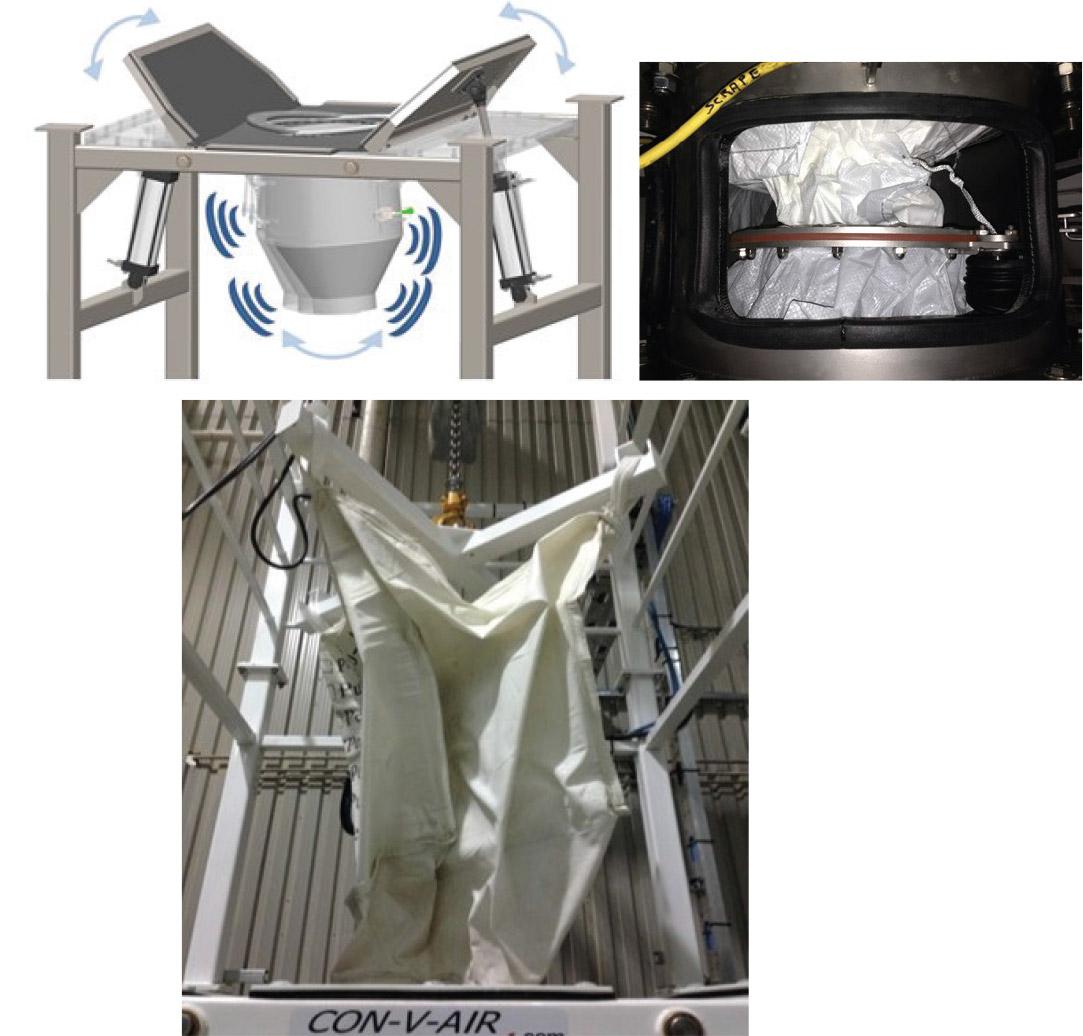

Dust control and bag conditioning

Vibrating access hopper

Not only the hopper allows the connection with the discharge of the flexible container and your process equipments, if offers all the features that you expect to find on such a device. It is, in addition, equipped with an air or electric vibrator. The action of these vibrators allows an optimal fluidity in the critical transition zone between the storage part (upper part) and the process (lower part). This optimized fluidization ensures a continuous and constant supply to the process.

Condition kit

A bag bottom massage system fluidizes the compacted materials allowing their free flow. This simple and reliable system, is designed to support and fluidize the contents of the heavier flexible containers!

Dust extraction system

The CON-V-AIR bulk bag "BBU" incorporates a dust extraction system that provides a cleaner work environment. This same suction system intervenes intensively at the en of the flexible container emptying sequence and complete the cycle. Once the bag is effectively emptied using the bag conditioning kit and vibrating hopper, the suction system removes as much of the contents of the flexible container as possible, thus ensuring optimal recovery of the solid bulk.

- Tel: 450 462-5959

- info@con-v-air.com

©2026 - CON-V-AIR inc.

Enlarged view

Enlarged view