Lime Milk Solution Preparation

Our goal is to facilitate handling dry hydrated lime and dry powder quicklime and render them as operator friendly as their liquid counterparts. We recognize the economic and chemical benefits of using lime in your process and realize that these benefits can be even greater when implementing a well designed system to handle the task. We have also seen and appreciate the problems that many operators are faced with when using poorly designed solution preparation systems.Components

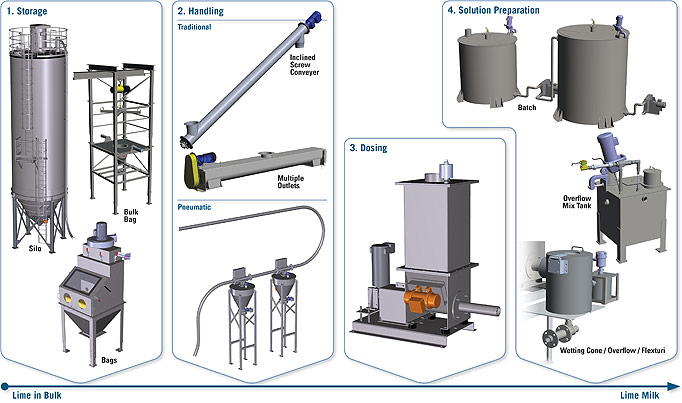

Lime milk solution systems require proper selection of essential components in the following stages:

- Storage

- Handling

- Dosing

- Wetting

The first step consists of selecting the type of storage equipment and capacity that is needed (1). Next, the method by which the lime milk be transferred is selected; traditional or pneumatic (2). The final step combines the dosing and wetting process. Here, batch or continuous methods will be selected depending on, among other criteria, location of dosing point (4).

Enlarged view

Enlarged view

In an effort to reduce these problems we have designed our systems to benefit from the following:

Storage

- Silo complete with cone activation system that promotes lime flow in the cone as well as within the silo walls

- Bulk Bag Unload station complete with vibrator and bag jostling system designed to empty 1 ton bags

- Bag Dump Station complete with hopper fluidising system and integral dust collection system providing dust free operation while transferring product

Handling

- Cast iron rotary valves complete with steel rotor to ensure dust free operation

- Pneumatic transfer of dry powder lime right to the point of injection eliminates risk of line clogging due to calcination/scaling

- Stainless steel volumetric screwfeeder designed and calibrated for lime applications

Traditional System

Our traditional system consists of preparing solution in tanks located directly beneath the storage silo or hopper. Volumetric screwfeeders, specifically calibrated for lime, feed the required dry powder lime directly into the tanks.Water is fed to the first tank, called the mixing tank, through a liquid eductor. The material feed inlet of the eductor is piped directly to the mix tank. Optimal solution concentrations of 5%-10% lime/water are attained. Once the solution prepared it is transferred, via peristaltic pumps, to the distribution tank. The traditional system is a time tested lime milk preparation method that has proven effective over the years.

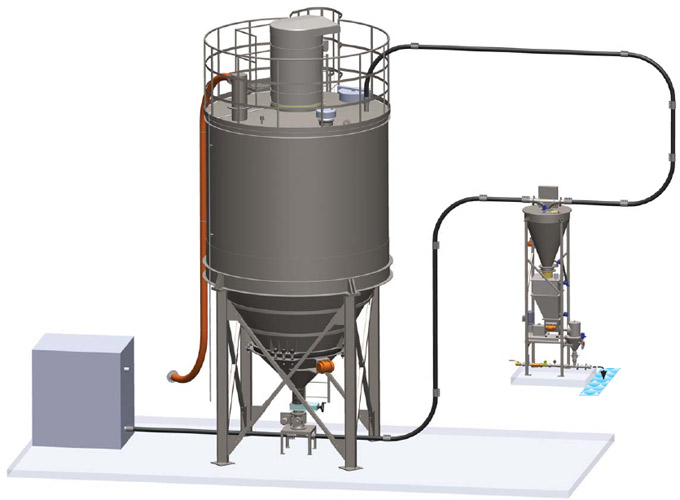

Pneumatic Handling

One of the advantages of using dry hydrated lime is that it does not have the tendency of calcinating in the transfer lines. This allows users to pneumatically convey right to the dosing point eliminating the need to have flexible tubing that may require maintenance to remove scaling.To accomplish this transfer a blower system is installed in close proximity to the storage silo/hopper and the dry hydrated lime is pneumatically transferred, in essence blown, through rigid steel pipes right to the dosing point. This system allows operators the flexibility of transferring the required lime to a single or to multiple dosing points within the plant. Located beneath the receiving hopper the screwfeeders dose the correct amount of lime directly into the mix tanks located above the dosing point which then overfeed into the water to be treated.

Alternatively, in applications where the mix tanks cannot be located directly above the dosing point, a wetting cone/flexible ejector combination is used. The wetting cone provides instantaneous mixing of lime/water without any accumulation of solution within the cone.Documents

Lime Milk Solution Preparation

HLS - Hydrated Lime Injection System

|

This system allows operators the flexibility of transferring the required quantity to a single or to multiple dosing points within the plant. On the receiving end the product is fed into one of two types of receivers; an intermediate receiver, which incorporates a valve system that allows product to fill the receiver while letting air passthrough, or an end of line receiver which incorporates dustcollection capabilities. Whether dust collection is performed on the end hopper or back in the silo itself the filter media is effective to 99.99%. Cleaning of the filter media is done automatically via an integrated pulse jet system thereby extending filter media life. Located beneath the receiving hopper the screw feeder doses the correct amount of lime directly into the wetting drum or wetting cone located above the dosing point which then feed into the water to be treated by our Flexturi. This configuration eliminates the need for pumping lime milk and minimizes operator/maintenance intervention due to scaling. Characteristics

Process Capability and Requirements

|

|

Documents

HLS

Hydrated Lime Injection System

|

Enlarged view Enlarged view |

The hydrated lime injection system is designed to eliminate problems related to injecting hydrated lime in your process. Storage, handling, dosing and feeding have been engineered to reduce maintenance and keep the plant clean. High-efficiency filters, seal-tight enclosures and vacuum wetting device have all been designed so you can enjoy the cost benefits of using hydrated lime in your process and keep the operating cost to a minimum.

Documents

Hydrated Lime Injection System

- Tel: 450 462-5959

- info@con-v-air.com

©2023 - CON-V-AIR inc.